- Memorandum of understanding with NYK

- Sustainability Bond

- Carbon-neutral AN

- Enaex Peru & H2 Perú

- BBBEE Certification

- Solar-powered plant

- Let's go to Expomin 2023!

- Women’s leadership

- 2022 Opex Workshop

- MTi Group

- O-Pitblast

- New DaveyTronic® plant

- 500 Women in mining

- Award Valor Inovação Brasil 2022

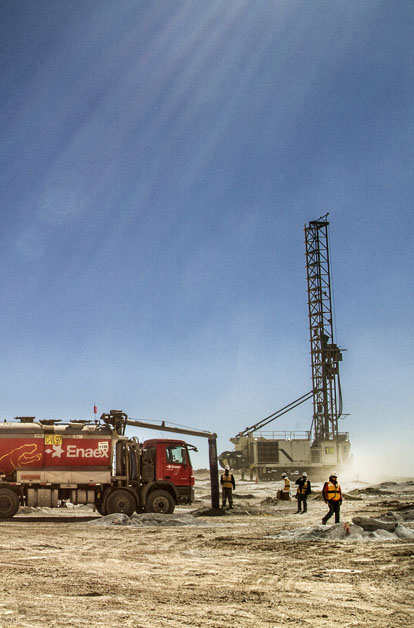

- Our Ecotruck

- Enaex Robotics in 2022

- Enaex Challenge 2022

- HyEx

- Director Application process

- Dow Jones Sustainability Index

- MINExpo

- Green ammonia

- Publication of Information Management Manual

- Acquisition of Downer Blasting Services

- First shipment of ANPP