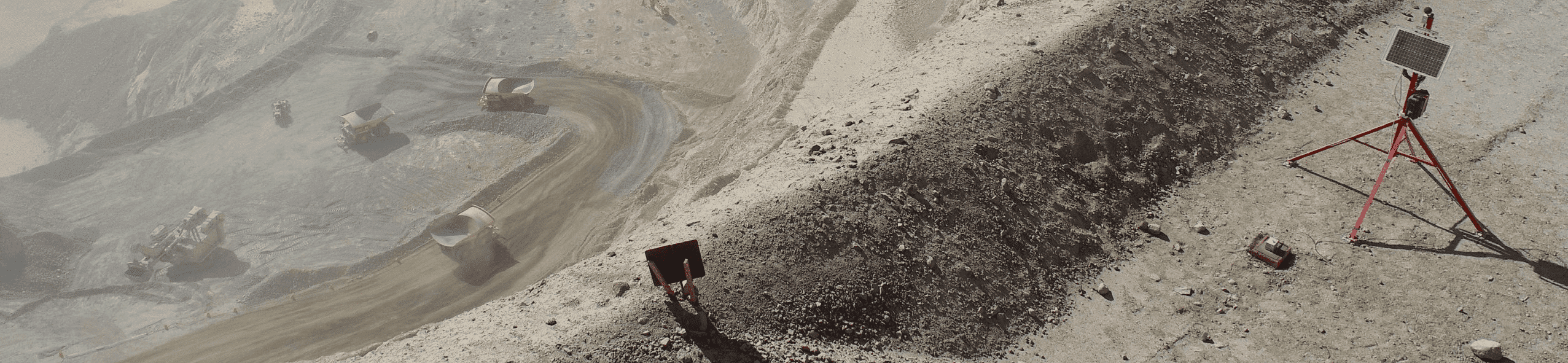

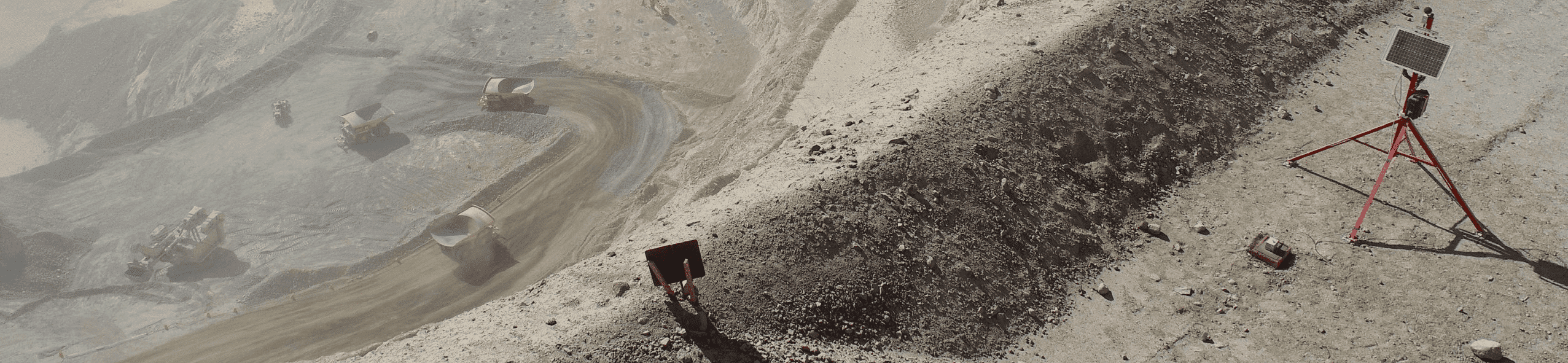

Control the impact of mining activities on the mine site

The Zaldivar mine is a copper mine located in the Antofagasta Region, Chile. It is located nearby another mine, considered as one of the largest copper mine in the world. Due to their recent neighbor’s landslide that partially covered a ramp and its intense activity, Zaldivar requested a solution to be able to monitor the impact of mining activities on their mine site.

“The fact that Enaex provides this kind of solution generates enormous added value to us. The system is quick to install and very easy to use. We can, daily and in real time, control what is happening in the mine, our blasting activities and nearby mines activity.”

Edwin Piñones,

Superintendent of Drilling and Detonation at CMZ Zaldivar Mine

Monitor and use real-time data

The Blast Site Watch (BSW) system integrates sensors to continuously monitor parameters such as airblast, wind, dust and vibrations. It’s quick to install and solar-powered. It provides through Enaex Bright, our digital platform designed for blasting optimization, real-time data about the mining operation impacts on the mine’s infrastucure and its neighbouring communities.*

The system is able to automatically compute the Devine model with historical data and predict the level of vibrations (or peak particle velocity) of future blasts, according to location, quantity of explosives and design of the blast. After the blast, the measured values versus the predictions are checked.

BSW generates continuous online reports and automatic alerts that are analyzed by Enaex geotechnical specialists (EMTS).

Mitigate disruptions caused by mining activities

The information is currently used in periodic meetings with the customer to provide transparent and reliable information about the status of mine operations. With BSW, we were able to confirm that the detonation activities were not causing disruptions.

The vibrations generated by the nearby mine were measured and identified. Thanks to that tool, our customer can promote a sustainable and responsible mining operation and control each step of the detonation process

We knew that our customer was already using Enaex Bright, our digital platform designed to optimize operational processes but it did not include the blast output parameters such as vibrations and airblast that would allow the client to verify the results of the blast.

Therefore, it was important for the customer and for us to make these data available in order to increase sinergies between operational data.

Thanks to innovation and data intelligence, our customer’s confidence increased significantly as it is now possible to demonstrate that our operation is maintained within defined parameters.