Reduce coarse fragmentation through sectorization of P80

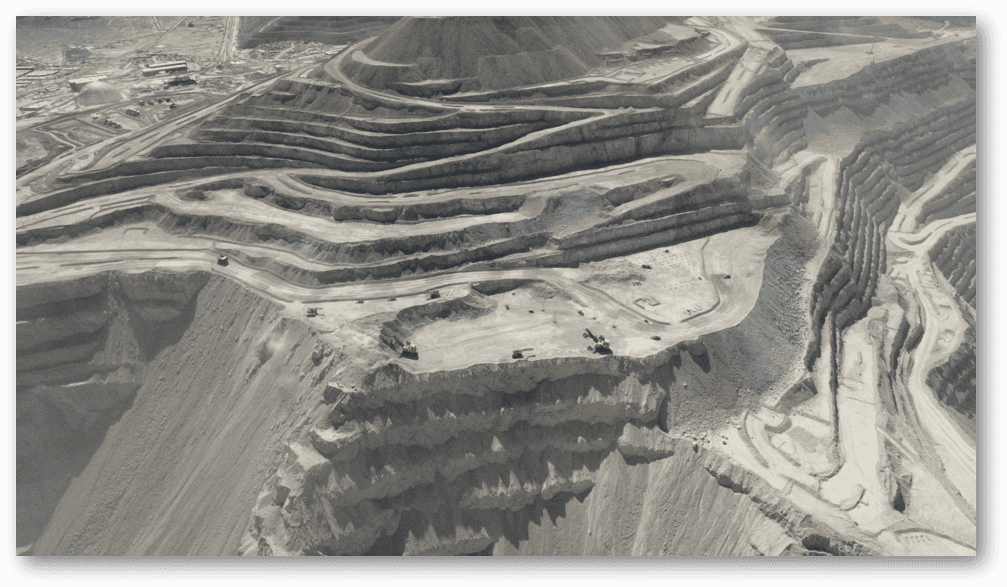

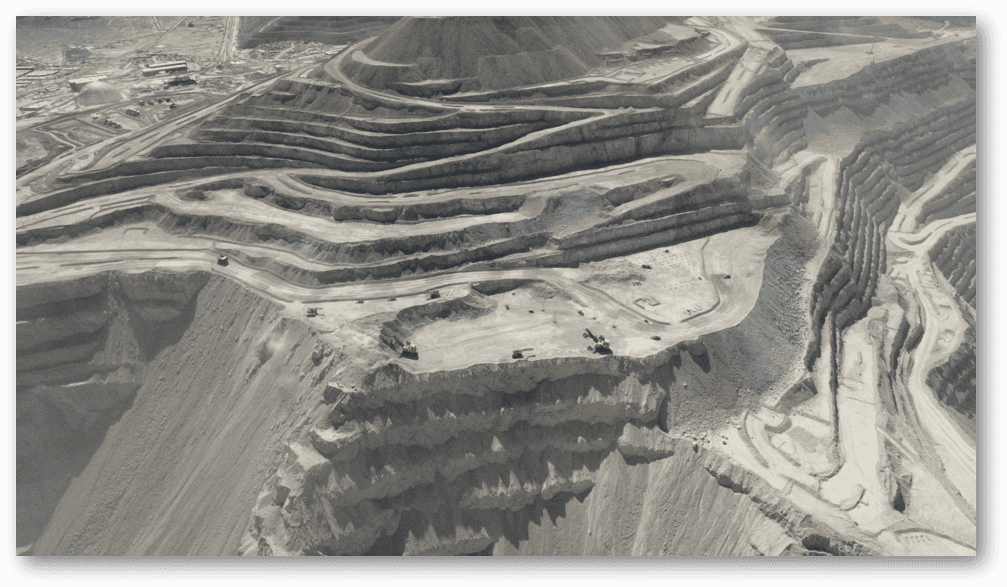

The Zaldivar Mine owned by AMSA is located southeast of Antofagasta, Chile. It is an open-pit copper mine that recently faced some issues during the blasting process of Phase 8 (F8). The post-blasting process was affected due to coarse fragmentation, which resulted in higher-than-expected fragmentation in a particular area. This, in turn, had an adverse impact on the performance of the loading, conveying, and crushing equipment, thereby increasing the cost of these processes.

“After conducting a technical analysis of post-blasting results, the EMTS team implemented improvements to address performance issues in the downstream process, transport, crushing, and plant. These changes allowed for better fragmentation based on design modifications and load factor adjustments.”

Esteban Vásquez,

AMSA’s Senior Drilling and Blasting Manager

Design optimization

Our team conducted daily fragmentation logs using WipFrag and the in-line fragmentation system installed on the shovels (ShovelCam). By doing so, we were able to identify areas with high levels of fragmentation. We drew polygons around these sectors to delimit them. After identifying the areas with coarse fragmentation, our EMTS team proposed an 8% reduction in the geometric configuration of the drilling design (BxE).

Mauris et elit ex. Suspendisse potenti. Interdum et malesuada fames ac ante ipsum primis in faucibus. Vestibulum fermentum ante a dapibus iaculis.

We have successfully obtained the expected fragmentation results for UGTB 8

After implementing the solution, the cost of drilling increased, resulting in the need for more wells. However, based on our simulations, the fragmentation (P80) results improved from 13.3 inches to 10.5 inches, which allowed us to enhance shovel performance and extraction, meeting the crushing requirements. The field tests confirmed our simulations, with a fragmentation in P80 of around 9 to 10 inches.

Prior to the sectorization project that utilized fragmentation data, the available information was solely utilized for reporting purposes. However, by plotting these values on a blueprint that includes geological and geotechnical data, it becomes possible to gain a better understanding of how explosives behave in conjunction with detonation mesh configurations. By implementing changes to the mesh reduction, we can improve downstream results in shovel performance, crushing, and adjust the outcomes based on the processing plant’s input targets. This optimization results in a more efficient and effective process.

We strengthened our bonds with AMSA, collaborating closely with the Drilling, Detonation, and Geotechnical areas of the Zaldivar mine to monitor and improve the results of our project.