Optimizing the blasting process in underground mining

The client’s mining complex is a set of underground gold and silver mines in Santa Cruz province, in the Argentinean Patagonia. Our customer was using non-electronic detonators for development. They sought a solution to reduce over-excavation and optimize the blasting process.

Use electronic initiation systems

The DaveyTronic Swift® electronic initiation system is designed for blasting in tunnels and underground mines to increase safety, advance development, and reduce over-excavation and cycle times.

Its main benefits are:

A blasting process that is both optimized and safer

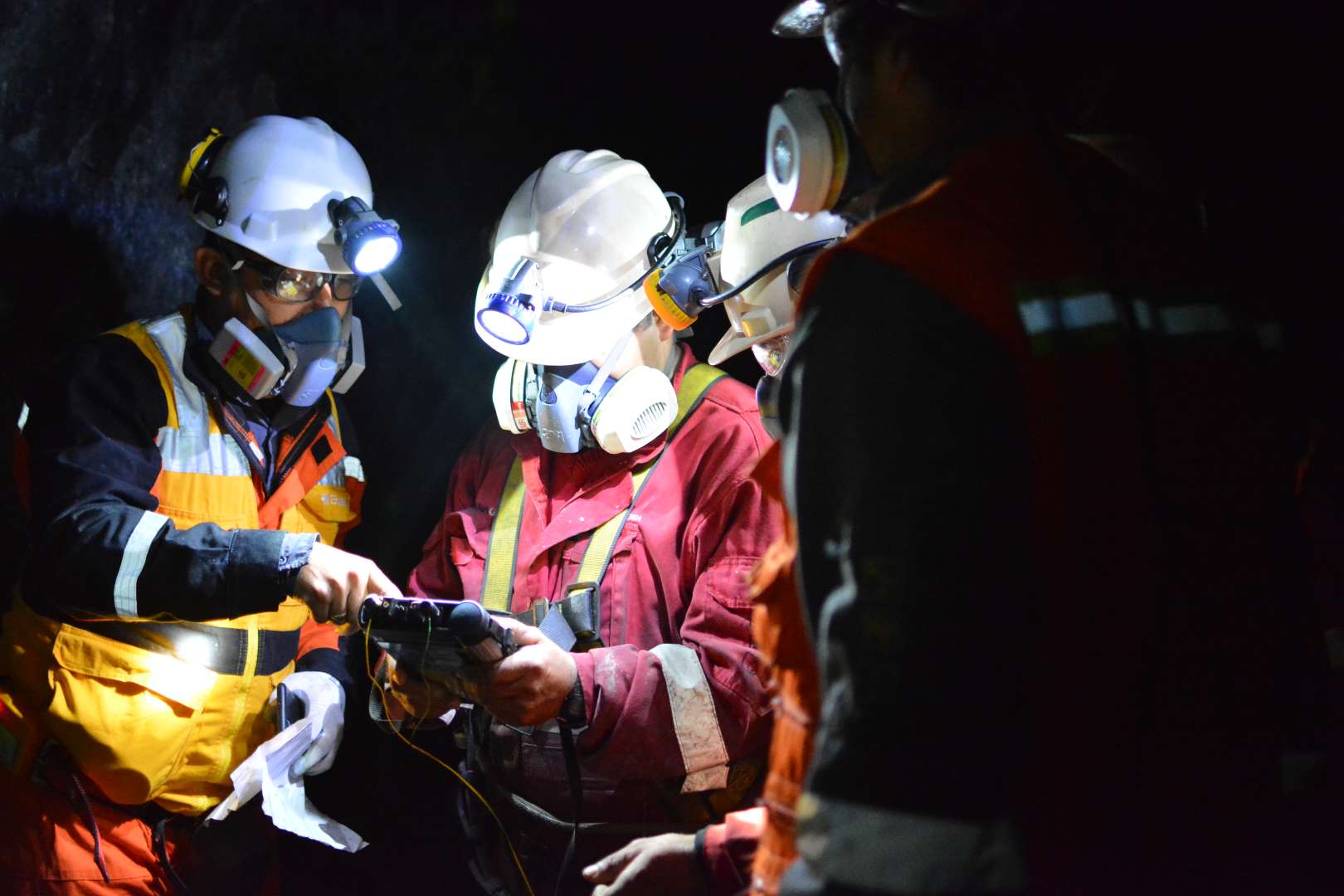

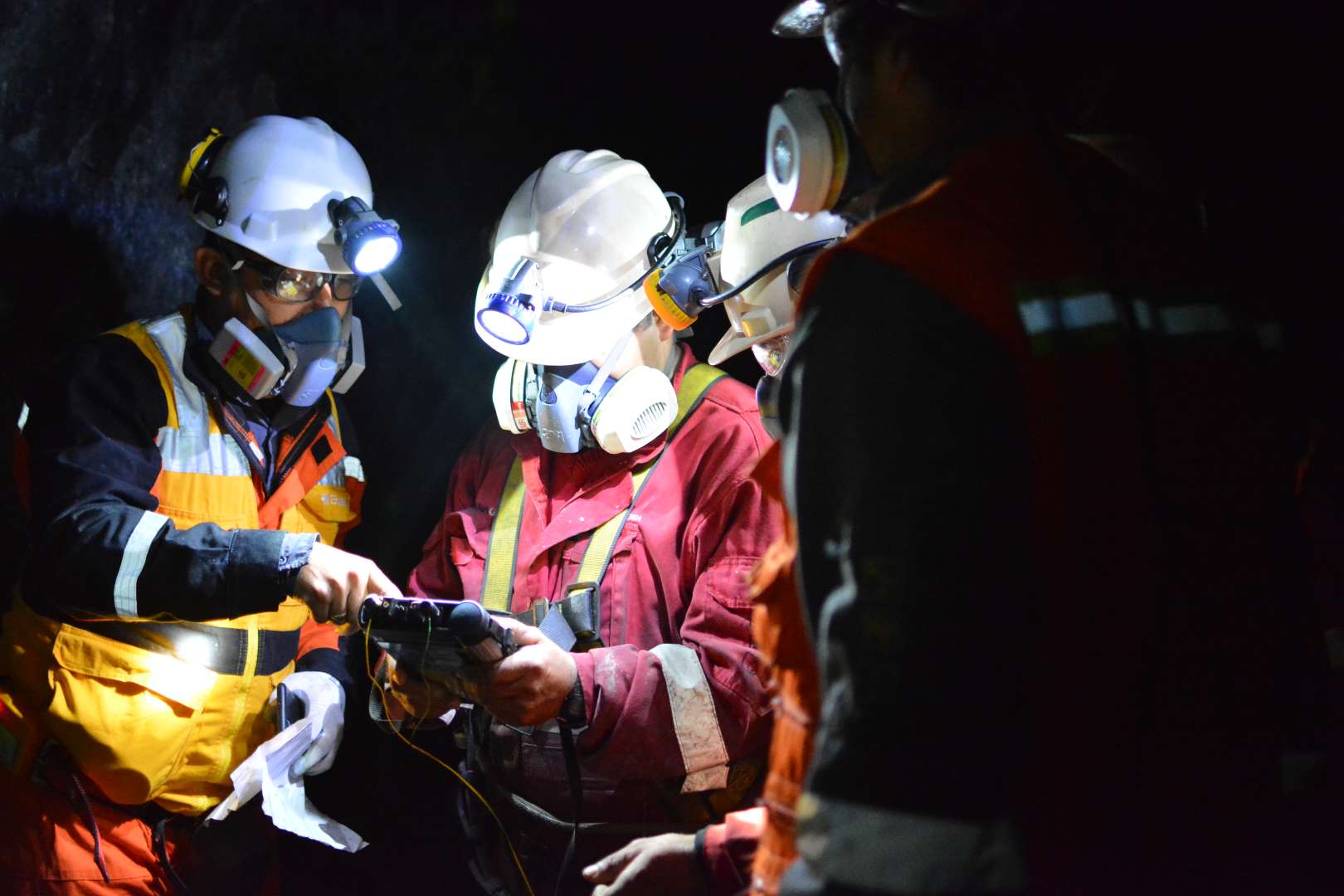

We utilized Swift detonators to initiate the opening of the mine portal. The DaveyTronic Swift® technology allowed us to decrease over-excavation by 4%, resulting in an over-excavation of 10.5% as opposed to the 14.5% achieved with non-electronic detonators. Additionally, we reduced loading times by 10 minutes per cycle while improving fragmentation. With non-electronic detonators, fragmentation reached 382mm, but with the DaveyTonic Swift®, we achieved 303mm. Furthermore, the advance performance was at 98%.

We created stronger bonds with the customer by proposing a new product to improve the safety and performance of their operations. In 30 blasts, we confirmed the benefits of DaveyTronic Swift® in the field. In addition, we quickly trained the operators so that implementing this new technology would be optimal and agile.